Advantages of Custom Cable Design, Engineering and Overmolding

Custom cabling is essential for many electronic applications. A custom-made wire or cable design is customized to meet your exact specifications and fit within your budget. The process of creating a customized wire or cord assembly includes several phases, including prototyping and extensive testing to ensure proper fit and function. Once the final product has been designed, you can expect a quick turnaround and no surprises. You’ll also get a comprehensive production plan, along with the tools needed to complete the job.

You can use a free online cable design tool to design a custom cable assembly. These tools have a library of standard cable sets and a flexible design tool. The engineers then evaluate your requirements and generate competitive quotes. These online tools are updated frequently, and the data is never locked into them. You’ll always have access to the full details of your design at any time. A custom cable design will be the ideal solution for your next project.

While a standard cable assembly might have a single-use component, a customized group can incorporate more device functionality. Custom cable assembly requires unique materials, tool design, and processing. Fortunately, Minnesota Wire offers a variety of materials and can work with you to determine the best ones. This allows you to make the best selection for your project. Contact us today if you’d like to get started on your next custom cabling.

Conductors: The main component of any cable is the conductor. It carries the signal and energy. The conductor is an essential part of any electrical system and is crucial to the end product’s performance. Various types of conductors are used in different cables. Copper, silver, nickel, and aluminum are the most common materials. In addition, many wires are coated with various materials. A typical application is Mylar.

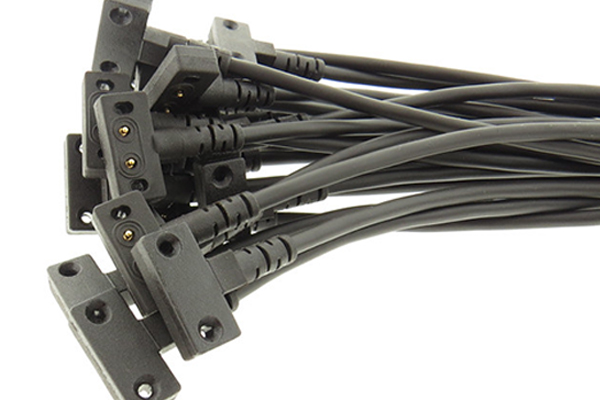

A custom cable design can be manufactured to meet your specifications. Depending on the length of the cable, it can be trimmed or made as long as the project requires. Unlike pre-made cables, a custom cable assembly can be manufactured in the exact size needed for your project. This type of installation allows you to hide the wires and connect them to other components. And because you are working with a manufacturer, you’ll be able to specify the materials and manufacturing processes to meet your specifications.

Custom cables are an essential part of many industries. For example, the military uses them to transmit vital information across vast distances. Because of the high-pressure environment, the cables must be highly resistant to harsh environments and have excellent performance. A custom cable manufacturer can provide you with the perfect cable for your project. Besides military applications, they are also used in the aerospace industry. The precision of a precision cable is essential to a plane’s performance.

A custom cable is manufactured in a small-scale setting. It requires more tooling than a standard cable. But the results are well worth the effort. You’ll get a high-quality custom cable that fits your exact specifications. This is also a cost-effective option for small-scale production. It is essential to keep in mind that the price of custom cables can vary considerably. However, they’re generally priced relatively high, so you can choose them in the length that suits your needs.

Whether you need custom cabling for a medical device, a robotic arm, or an automated kiosk, there are thousands of applications for custom cables. These cables are used in massive machinery to transmit power or signals. In addition to this, they’re used in various devices such as terminals, automated kiosks, and continuity testing instruments. The exact specifications for custom cable assembly vary between industries. When choosing a custom cable, look for a reliable custom wire and cable provider.

If you’re looking for a custom wire or cable, consider the custom cable manufacturer’s materials, certifications, and knowledge. They have the expertise and equipment to design, engineer, and manufacture a variety of custom cable options. In addition, a custom cable manufacturer should be able to offer a wide variety of options for conductors, including single- and multi-conductor cables. The most appropriate custom wire or tube type will depend on the intended application.